Glossy Polyester DTY: A Versatile Yarn for High-Performance and Aesthetic Textile Applications

2025-06-25

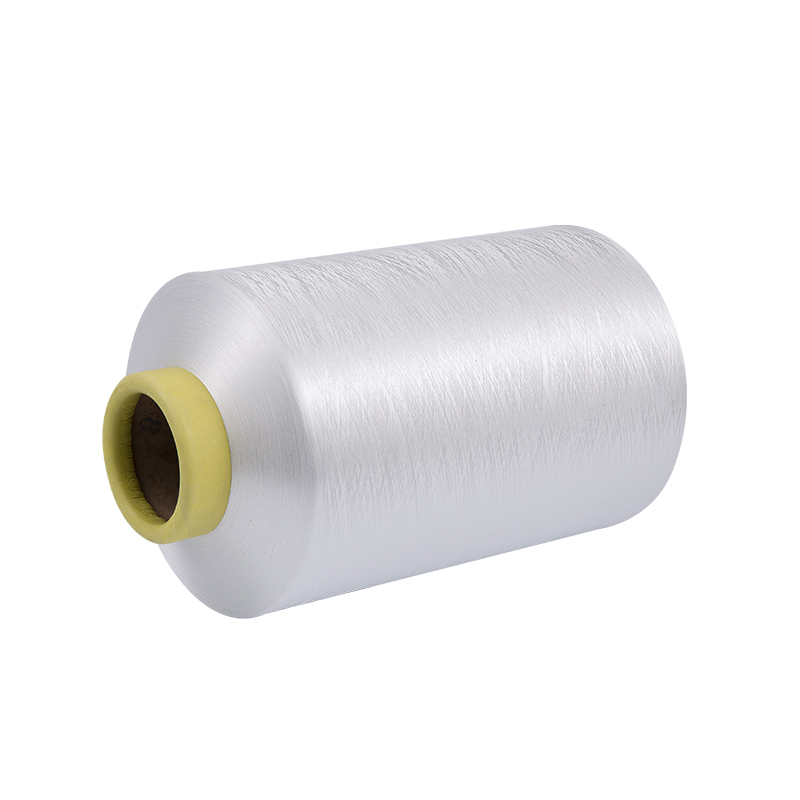

In the dynamic and ever-evolving world of synthetic fibers, Glossy Polyester DTY (Draw Textured Yarn) has emerged as a key material that bridges the gap between functionality and aesthetics. Known for its lustrous appearance, excellent elasticity, and durable characteristics, Glossy DTY is playing an increasingly important role in high-performance textile applications—from fashion and sportswear to home furnishings and technical fabrics.

What is Glossy Polyester DTY?

Glossy Polyester DTY is produced through the draw texturing process, in which Partially Oriented Yarn (POY) is drawn and simultaneously textured using a combination of heat and twisting. This process gives the yarn a crimped, soft, and stretchy structure, which mimics the feel of natural fibers while maintaining the superior strength and wrinkle resistance of polyester.

What sets glossy DTY apart from standard DTY yarns is its shiny surface finish. This is achieved by using specially treated filaments during the POY stage or by adding functional finishes during the texturing process. The resulting yarn exhibits a smooth handfeel and a subtle yet elegant sheen that enhances the visual quality of the end fabric.

Key Features and Advantages

1. High Luster Finish

The glossy surface of this DTY variant adds a refined and premium look to fabrics. It is especially popular in fashion-forward applications where surface aesthetics are a priority, such as lingerie, blouses, linings, and decorative scarves.

2. Elasticity and Softness

Glossy DTY offers excellent stretch and recovery properties, making it ideal for stretchable knitwear, leggings, and activewear. The yarn retains shape and provides comfortable elasticity without compromising on strength.

3. Color Versatility

The yarn can be supplied in raw white, dope-dyed, or package-dyed options. Dope-dyed glossy DTY, in particular, offers superior colorfastness and environmental advantages by reducing water usage and effluent during dyeing.

4. Durability and Wash Resistance

Like all polyester-based yarns, glossy DTY maintains high resistance to shrinkage, abrasion, and chemicals. This makes it a long-lasting solution for both everyday garments and industrial textiles.

5. Excellent Spinnability

Its uniform structure and reliable physical properties make it compatible with a variety of fabric production processes, including warp and weft weaving, circular knitting, and flat knitting.

Application Fields

Thanks to its balanced performance and elegant finish, Glossy Polyester DTY is suitable for a wide range of end-use markets:

• Apparel

In the fashion industry, glossy DTY is widely used in women’s dresses, tops, intimate wear, and accessories. Its sheen adds visual depth, while its stretchability supports body-hugging designs.

• Activewear and Sportswear

When blended with spandex or elastane, glossy DTY becomes a high-performance component in yoga pants, gym apparel, and outdoor gear, offering flexibility, durability, and moisture-wicking capabilities.

• Home Textiles

In home décor, glossy DTY is incorporated into curtains, upholstery, cushion covers, and bed linens. The luster enhances the fabric’s decorative value, while its resilience ensures long-term use.

• Technical Textiles

Beyond fashion, Glossy DTY is increasingly used in automotive interiors, industrial linings, and filtration fabrics, thanks to its strength and thermal stability.

Sustainability Potential

With growing demand for eco-conscious textile solutions, many manufacturers now offer glossy polyester DTY made from recycled PET (rPET). This allows brands to maintain the desired aesthetic and mechanical properties of traditional glossy yarn while minimizing environmental impact. Recycled glossy DTY is fully compliant with global sustainability standards such as GRS (Global Recycled Standard) and supports circular production models in the textile sector.

Customization Options

To meet the diverse requirements of global markets, Glossy Polyester DTY is available in a range of:

Denier and filament counts: From fine denier (75D/36F) for lightweight garments to heavy denier (300D/96F) for upholstery.

Intermingling types: SIM (Slight Intermingled), NIM (Non-Intermingled), and HIM (High Intermingled), depending on fabric texture requirements.

Cross-section shapes: Including round, trilobal (for enhanced gloss), and hollow fibers for added warmth or moisture control.

These options allow fabric manufacturers and designers to select yarns tailored precisely to their desired texture, weight, and finish.

Market Outlook and Industrial Significance

As global textile demand shifts toward performance materials with visual appeal, Glossy Polyester DTY is well-positioned to lead in multiple application categories. With continuous innovation in spinning, dyeing, and sustainability practices, the yarn continues to attract attention from both high-end fashion houses and functional textile producers.

Textile companies that adopt glossy DTY gain access to a versatile material that aligns with modern consumer expectations for beauty, functionality, and responsibility. Its affordability, wide availability, and compatibility with advanced production technologies make it a reliable material across the textile supply chain.

Conclusion

Glossy Polyester DTY represents a thoughtful fusion of technical performance and aesthetic finesse. Whether used in fashion, furnishings, or functional products, it offers the characteristics that today’s market demands: elasticity, elegance, and endurance. As the textile industry continues to explore new frontiers in design and sustainability, Glossy DTY remains a material that brings innovation to the surface—literally and figuratively.

English

English 中文简体

中文简体 Español

Español عربى

عربى